No posts

Business Spotlight: Fourbital Factory

Keeping Textile Waste Out of the Landfill

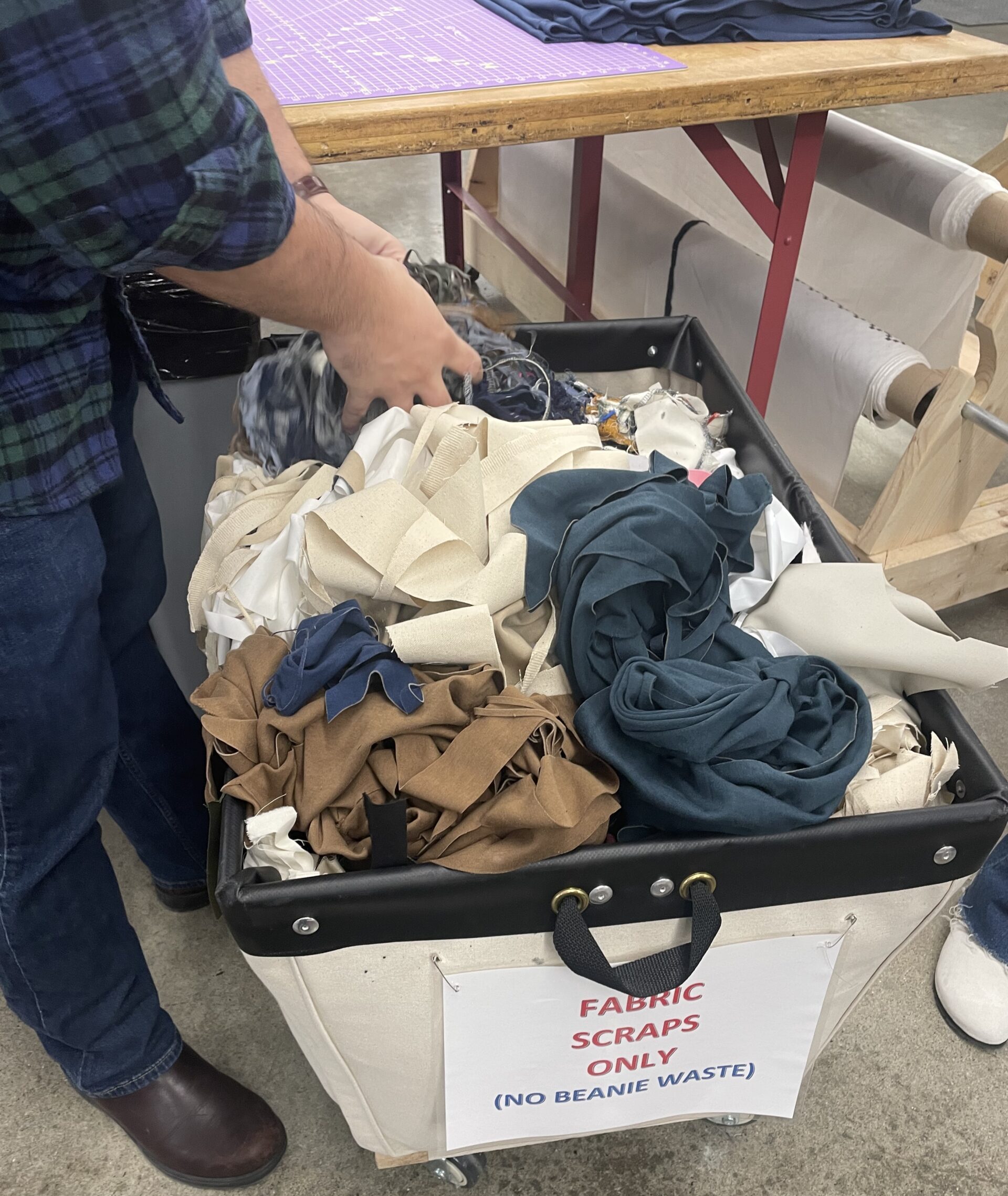

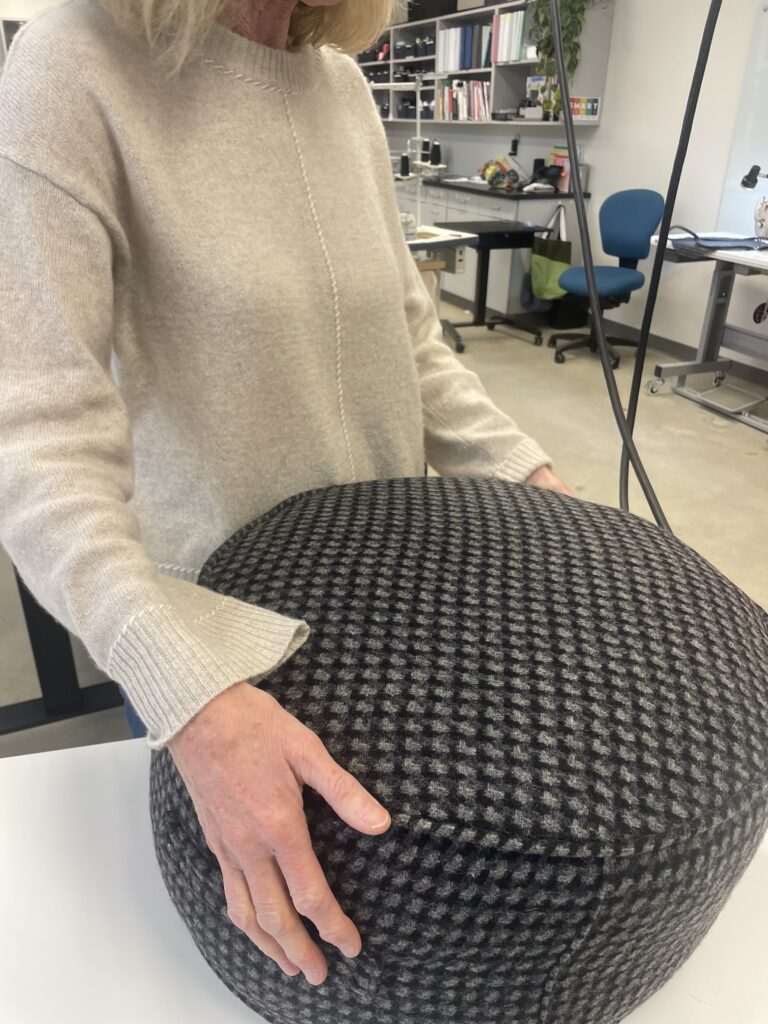

Since Fourbital Factory’s opening in Burlington three years ago, they have made it their mission to ensure that not a single piece of their textile waste ends up in Vermont’s only landfill. Thanks to a grant from the Chittenden Solid Waste District (CSWD), they have taken that commitment even further by purchasing a textile shredder that transforms fabric scraps into stuffing for their floor poufs.

Finding a shredder that fit their scale and needs was no small feat. It took years of research to find one that matched their budget and ideal size. But at the end of 2024, their vision finally came to fruition with a textile shredder delivered and installed in their Burlington factory. And now each of their handmade floor poufs is packed with 20 pounds of shredded textile waste, giving new purpose to what would otherwise be discarded.

Turning Waste into a Resource

Fourbital Factory is giving textile waste a second life, not only as stuffing for floor poufs but also as a hands-on educational tool in their Continuing ThrED program. This program provides high school students, New Americans, and other community members with opportunities to participate in basic sewing workshops or even a certification course to develop the sewing skills necessary to find employment in the field.

Building on their workforce development and sustainability mission, they are offering a Sustainable Sewing Summer Internship for high school students to gain hands-on experience and contribute to sustainability projects, including operating the fabric shredder and making floor poufs. After the summer internship concludes, they plan to hire a graduate of their certification program for New Americans as a part-time operator for the textile shredder.

Fourbital Factory’s commitment to sustainability and community-building doesn’t stop at their workshops. They have donated floor poufs to local preschools, libraries, and the King Street Center, ensuring that their waste reduction mission also benefits the community in a tangible way.

Innovative Approaches to Waste Reduction

Recycling textiles is a complex challenge. While technology for recycling textile waste is still developing, Fourbital Factory is exploring multiple solutions. In addition to pouf stuffing, they collaborate with Apparel Impact to downcycle fabric shoddy into rags, insulation, and dog beds.

From the very start to the final stage of their manufacturing process, they are constantly looking for new ways to minimize their waste and responsibly recycle or downcycle the waste that they do produce. Their laser fabric cutter plays a key role in waste reduction by cutting fabric with exact precision, allowing them to maximize material use like a perfectly arranged puzzle.

A Model for Sustainability: Rethinking Waste

On average, people wear an item of clothing just seven times before discarding or donating it. Fourbital Factory’s work challenges this throwaway culture, reminding us to rethink our relationship with clothing and the waste it generates. Their commitment to sustainability extends beyond making floor poufs, it also creates opportunities for individuals, strengthens the community, and demonstrates the power of a multifaceted approach to waste reduction.

Their work proves that with the right resources and a little creativity, textile scraps can become so much more than just waste.